I was asked to make a kitchen cleaver to match the rest of my Forged Finish Range

I decided to make it full tang out of 3.5mm 440B stainless to be as strong as possible.

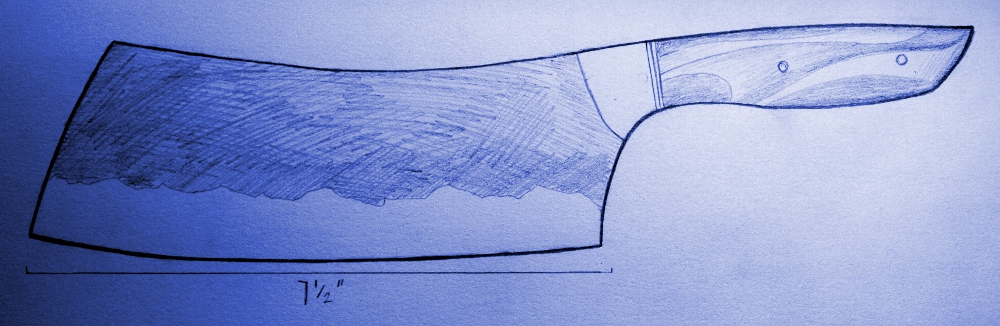

Here is my initial design.

I decided to make it full tang out of 3.5mm 440B stainless to be as strong as possible.

Here is my initial design.

The shape is designed to give maximum control with the balance favouring the weighty blade.

The handle's ergonomic shape allows a tight finger grip and just enough length for a large hand.

A metal bolster protects the top of the wooden handle from wear during heavy use.

The handle's ergonomic shape allows a tight finger grip and just enough length for a large hand.

A metal bolster protects the top of the wooden handle from wear during heavy use.

The bolster is aluminium and is riveted on with nickel silver - a soft metal alloy that will not snap under impact. The masking tape over the blade stops it getting scratched during the handling process.

I have hammered over the pins on the bolster and shaped the olive scales. It takes a while to select the best part of the grain to use for strength and beauty. This is one of the most beautiful pieces of wood I've had the pleasure of using. Next glue up, sand off and ...