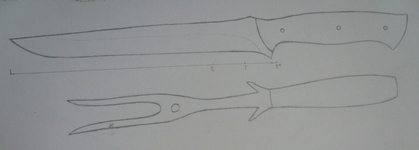

I was asked to create a specially made carving set to become a family heirloom. This is the initial design for the knife and fork. I gave the knife an 8'' full bellied but fairly thin blade to give control and dexterity when slicing meat.

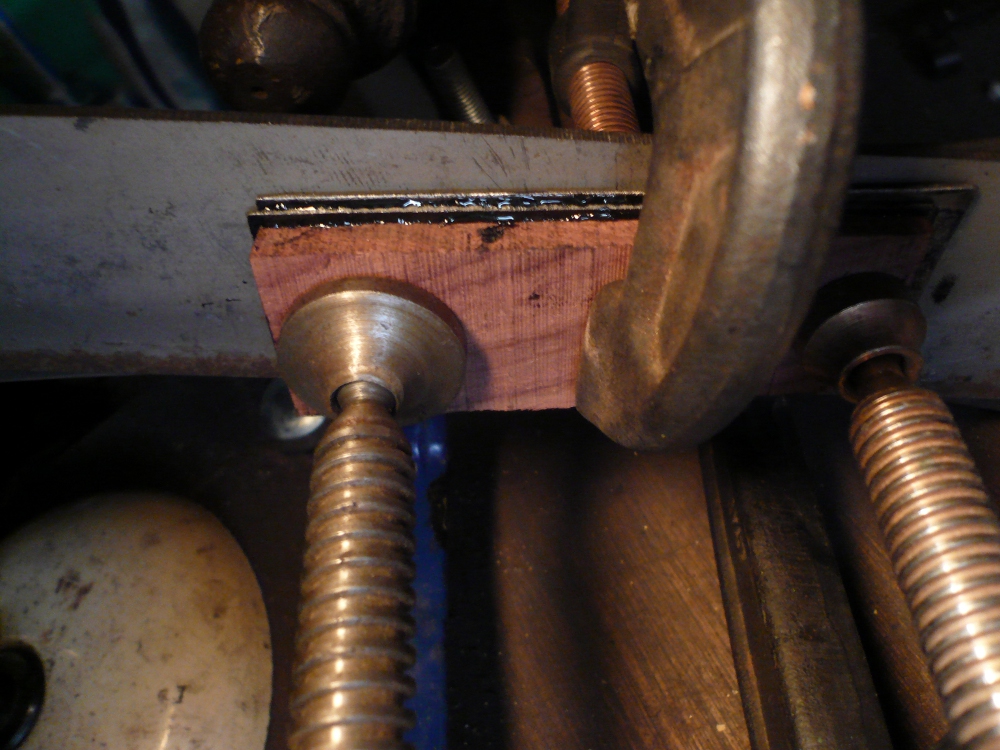

The customer took the option of an aluminium bolster and 5 spacers on a rosewood handle with stainless sandwich liners. These are most of the layers cut out and sanded ready for gluing up. Each has to be perfectly flat to make each layer meet in a clean line. The black layers are the vulcanised fibre - a layer introduced to increase the stength of the bond and give the handle more durability. Rosewood gives a great finish and doesn't mind getting a little wet.

I made the blades out of Sheffield SF100 high carbon razor blade steel and got them hardened to 59 Rockwell with a liquid nitrogen cryo-quench then double tempered.

I made the blades out of Sheffield SF100 high carbon razor blade steel and got them hardened to 59 Rockwell with a liquid nitrogen cryo-quench then double tempered.

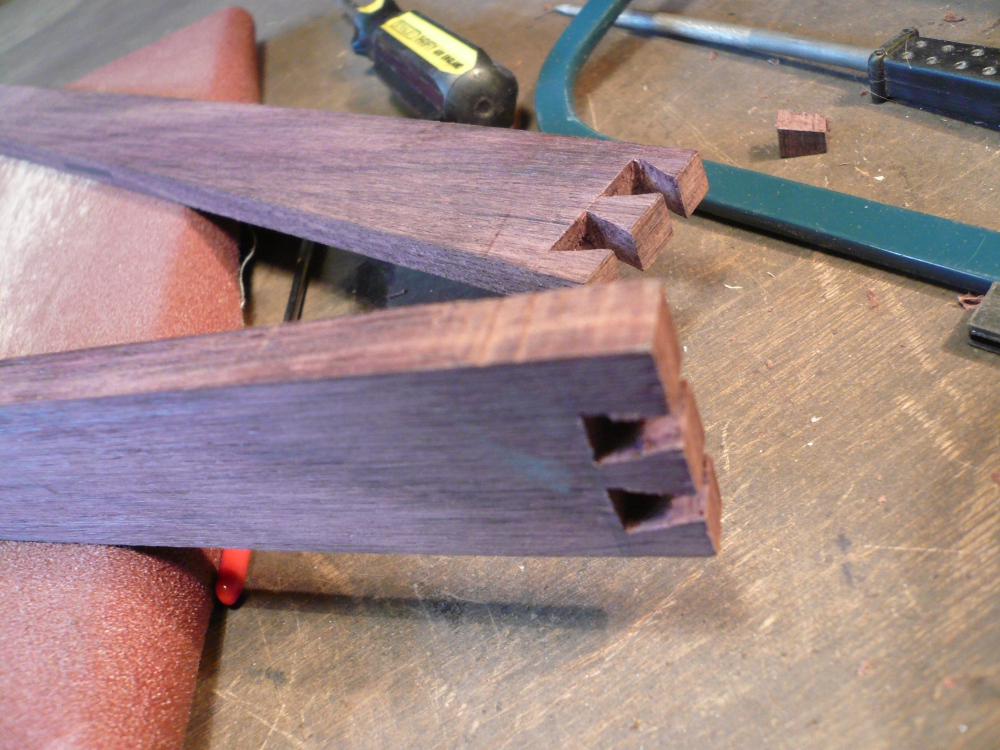

Next I made the aluminium bolsters and riveted them in place with nickel silver rod. Then I glued up the sandwich liners and spacers with a slow drying epoxy resin. While waiting for them to dry I made the rosewood box. The dovetails took a steady hand and were very satisfying when tapped together.

I put a layer of stainless in the lid with my signature wave filework with two layers of black fibre.

Here are the finished products:

I put a layer of stainless in the lid with my signature wave filework with two layers of black fibre.

Here are the finished products: