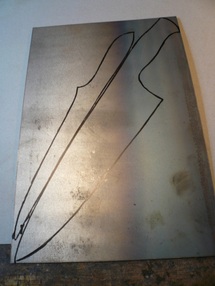

Here are the two custom knife sets I have just finished. The brief given was to design and make two sets of kitchen knives to the customer's specifications. One set with bolsters and black, white and brass spacers, the other with a simple yew handle. As well as the knives the customer wanted two custom made leather knife rolls.

The next stage was to work up the sanding grits to a 400 and then polish the blade to a 180 satine. I then drilled the holes in the handles, hardened and tempered the blades and then polished them again.

The brass bolsters are fitted first onto the handle, then riveted onto the blade with nickel silver rod.

The brass bolsters are fitted first onto the handle, then riveted onto the blade with nickel silver rod.

Next the yew scales were cut out and fitted onto the tang. Black and white vulcanised fibre and brass spacers were then carefully fitted.

I always look for interesting grains or patterns when choosing wood for handles. This yew has been seasoning for over 30 years!

I always look for interesting grains or patterns when choosing wood for handles. This yew has been seasoning for over 30 years!

Once the knives were complete I then started work on the leather roll. I sourced two beautifully tanned deer skins. I liked the deer leather as it is softer and more supple than cow leather while not as stretchy as sheep leather.

I formed the leather carefully around the knife handles and held it securely in place with stainless rivets.

The knife roll is secured with poppers and can be carried using a handle.

Finally I had the blades laser engraved with my logo and with a personalised message requested by the customer.

I formed the leather carefully around the knife handles and held it securely in place with stainless rivets.

The knife roll is secured with poppers and can be carried using a handle.

Finally I had the blades laser engraved with my logo and with a personalised message requested by the customer.