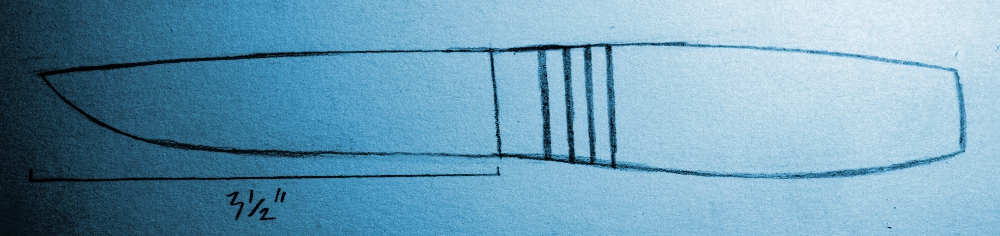

I was asked to make a wood carving knife using an olive wood log from Greece. The guy who commissioned it brought the log back from their Greek olive grove, so I could make this knife to celebrate his Dad's birthday. Underneath are some pictures to show how I made it.

The logs had quite a few cracks in (from an axe) so I first had to select the sound wood with an interesting grain. Squaring up helps throughout the build, and is safer when using the band saw.

The customer wanted the grain on the thin segments to run in different directions so I had to find the wood with no splits and a strong grain structure. Then sanding on a flat surface to get the spacers the same thickness.

The layers are then drilled out and assembled making sure all surfaces are flat and will show off the grain. The arrow is to line up the bolster with the main handle.

I've lined up the bolster and main handle then used slow dry epoxy resin with a tint of blue. Then I sawed off the excess then sanded it for a few hours, testing the shape and comfort of the grip.

'A fine knife,' I hear you say 'but where will it live?' Read on...

| The belt loop is glued then stitched on with heavy duty waxed nylon. Then glued together, stiched up and dyed. The final touch is some bees wax which waterproofs and conditions the leather and brings out the full colour. | The sheath is thick 5mm vegetable tanned leather from Clayton's Tannery in Chesterfield. The welt (cutting out left) is what protects the stitches from the blade. The shape of the welt is really important. It means the knife will fit snuggly and not fall out. |